Free-Standing Retaining Wall with Types

Free-standing retaining walls are structures designed to hold back soil and prevent erosion in various applications. They are widely used in civil engineering and landscaping to create terraces, and level surfaces, and provide stability to sloped areas.

This article explores the different types of free-standing retaining walls, their functions, and important considerations for their design and construction.

Retaining walls play a crucial role in supporting vertical or near-vertical grade changes and preventing soil movement. Free-standing retaining walls, also known as gravity walls, rely on their weight and mass to resist the lateral pressure exerted by soil.

Understanding the types of free-standing retaining walls and their specific functions is essential for effective design and construction.

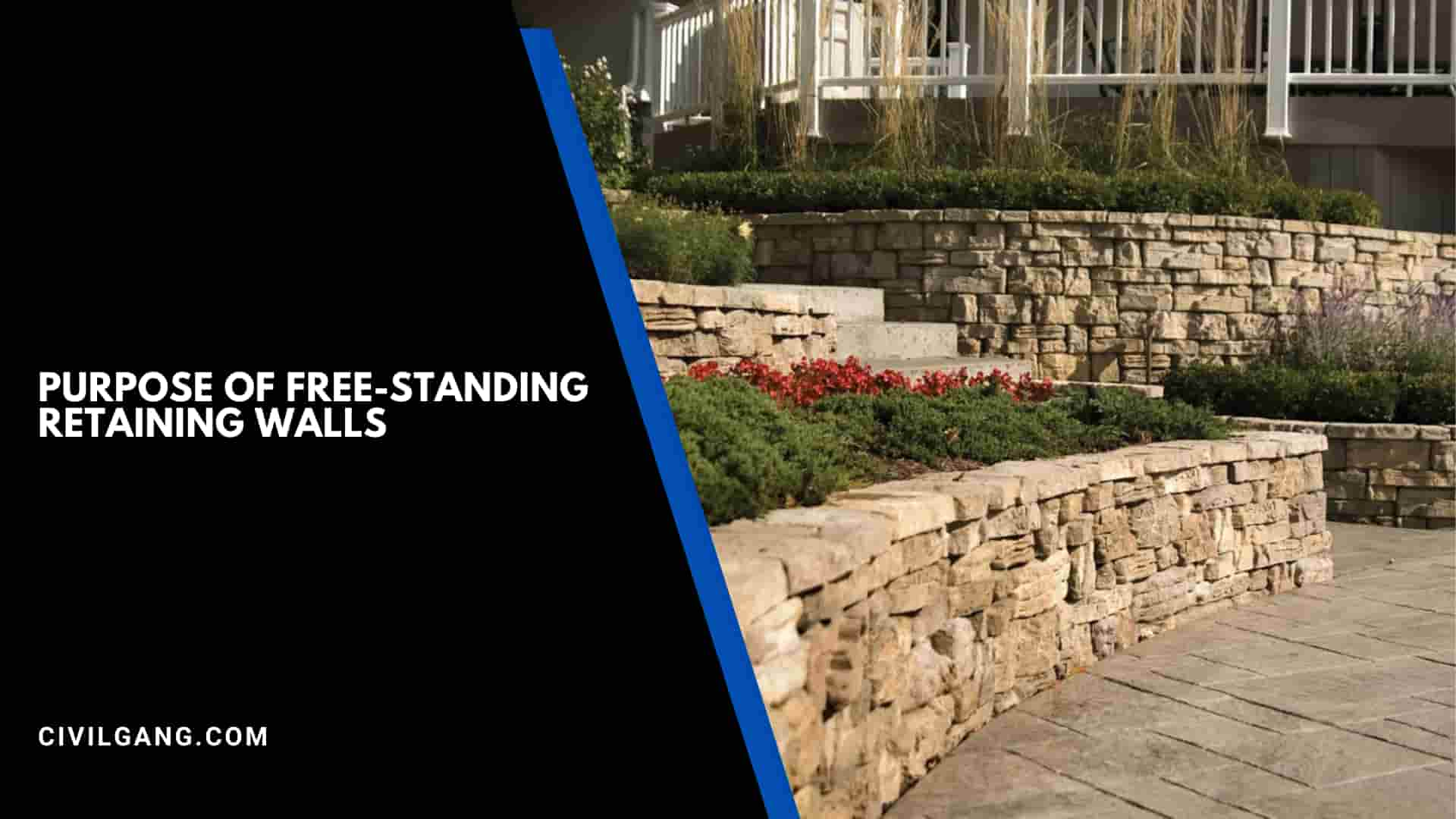

Purpose of Free-Standing Retaining Walls

The purpose of free-standing retaining walls is multifaceted, serving several important functions in civil engineering and landscaping. The primary purposes of these walls are as follows:

- Soil Retention: The main function of free-standing retaining walls is to hold back soil and prevent erosion. They provide a structural barrier that supports and stabilizes sloped or uneven areas, preventing soil movement and the loss of valuable land.

- Grade Change Management: Free-standing retaining walls are used to manage grade changes and create level surfaces. They allow for the creation of terraces, steps, or platforms, enabling the utilization of otherwise inaccessible or uneven land. This is particularly useful in landscaping projects, such as gardens, parks, and residential properties.

- Structural Support: Retaining walls provide structural support to resist lateral earth pressure and maintain the stability of adjacent structures. They are commonly used in infrastructure projects, such as highways, bridges, and railways, to support embankments, cut slopes, or stabilize cut-and-fill areas.

- Aesthetic Enhancement: Free-standing retaining walls also serve an aesthetic purpose. They can be designed to enhance the visual appeal of landscapes and provide architectural interest. With various materials, textures, and finishes available, retaining walls can be customized to complement the surrounding environment and improve the overall aesthetics of a site.

- Erosion Control: By preventing soil erosion, retaining walls contribute to erosion control and help maintain the integrity of natural landscapes. They protect against the adverse effects of water runoff, such as gully formation, sedimentation, and the degradation of nearby ecosystems.

- Functional Space Creation: Retaining walls can create functional spaces within landscapes. They can be used to define outdoor seating areas, and raised planting beds, or to support other elements such as fences, pergolas, or retaining wall benches. These walls add structure and purpose to outdoor spaces, increasing their usability and enhancing the overall design.

- Safety and Property Protection: Free-standing retaining walls improve safety by minimizing the risk of slope failures and soil movements. They help prevent landslides, avalanches, or the collapse of unstable soil masses, protecting both people and property from potential harm.

- Noise and Privacy Barrier: Depending on their height and location, retaining walls can act as noise barriers, reducing the impact of noise pollution from nearby roads, railways, or industrial areas. Additionally, they can provide privacy by shielding residential or commercial properties from adjacent public spaces or neighboring buildings.

By serving these purposes, free-standing retaining walls contribute to the overall functionality, aesthetics, and safety of landscapes and built environments. Proper design, construction, and maintenance of these walls are essential to ensure their effectiveness and longevity.

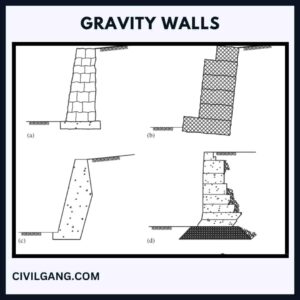

Gravity Walls

Gravity walls are the most common type of free-standing retaining walls. They rely on their own weight and the friction between the wall and the soil to resist the pressure from behind.

Gravity walls can be constructed using various materials, including concrete blocks, stone, brick, or timber. They are suitable for low to medium-height applications and can be easily constructed without the need for extensive reinforcement.

Free-standing gravity walls, also known as gravity retaining walls, are a type of retaining wall that relies on their own weight and mass to resist the lateral pressure exerted by soil.

These walls derive their stability from the force of gravity, as opposed to relying heavily on external reinforcements or anchors. The weight of the wall, combined with the friction between the wall and the soil, provides the necessary resistance against soil pressure.

The design and construction of free-standing gravity walls are based on the principles of equilibrium and stability. The primary purpose of these walls is to retain soil and prevent erosion, allowing for grade changes and creating level surfaces in various applications, such as landscaping, civil engineering, and infrastructure projects.

Key features and characteristics of free-standing gravity walls include:

- Self-supporting Structure: Free-standing gravity walls are designed to be self-supporting without relying on extensive external supports or tiebacks. Their own weight and the interlocking properties of the wall materials provide stability.

- Mass and Weight: The weight of the wall is a critical factor in its stability. Gravity walls are typically designed to be heavy and massive, enabling them to resist the lateral pressure from soil and retain the desired grade changes.

- Wall Geometry: Gravity walls can be constructed with various geometries, including vertical or near-vertical faces. The wall face may have a slight batter (inward or outward inclination) to enhance stability and aesthetic appeal. The wall’s dimensions, slope, and batter angle are determined based on the specific design requirements and soil conditions.

- Material Selection: Gravity walls can be constructed using a range of materials, including concrete blocks, natural stone, brick, or timber. The choice of material depends on factors such as aesthetics, load-bearing capacity, and availability. Concrete blocks are commonly used due to their strength, durability, and ease of installation.

- Backfill and Drainage: Proper backfilling and drainage behind the gravity wall are essential for its stability and long-term performance. The backfill material should be well-compacted and allow for adequate drainage to prevent the buildup of hydrostatic pressure. The inclusion of drainage systems, such as perforated pipes or geocomposite drains, can help manage groundwater and reduce hydrostatic pressure.

- Height Limitations: Free-standing gravity walls are generally suitable for low to medium-height applications. The specific height limitations depend on the design parameters, including the soil properties, weight of the wall, and desired safety factors. In cases where taller walls are required, additional reinforcements, such as soil anchors or tiebacks, may be necessary.

- Construction Techniques: The construction of gravity walls involves excavating a foundation trench, preparing a stable base, and interlocking the wall materials. Proper alignment and level of the wall blocks are crucial for structural integrity. Mortar or adhesive may be used to bond the blocks together, depending on the material and design requirements.

Free-standing gravity walls provide an efficient and cost-effective solution for soil retention, grade changes, and erosion control. Their self-supporting nature, combined with proper design and construction techniques, ensures their stability and durability in various applications.

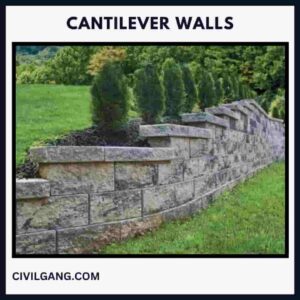

Cantilever Walls

Cantilever walls are another type of free-standing retaining walls that use leverage to resist soil pressure. They consist of a base slab, stem, and a horizontal arm called the toe.

The toe extends beyond the face of the wall, creating a counterbalance that helps stabilize the structure. Cantilever walls are more suitable for taller walls and can be constructed using reinforced concrete or masonry.

Cantilever walls are commonly used in civil engineering and construction due to their structural efficiency and ability to withstand significant loads.

They are designed based on principles of structural engineering, taking into account factors such as soil properties, wall height, soil loads, and required safety factors.

The key components of a cantilever retaining wall include:

- Stem: The vertical portion of the wall that extends above and below the base. The stem transfers the lateral soil pressure to the base.

- Base (Footing or Heel): The horizontal portion of the wall that provides the necessary support and resists overturning. The base is typically wider and deeper than the stem and is designed to distribute the loads evenly.

- Toe: The lower end of the wall that extends into the retained soil. The toe provides additional stability against sliding.

- Backfill: The soil placed behind the wall exerts lateral pressure on the structure. The properties of the backfill, such as compaction, drainage, and friction angle, are considered during the design process.

- Reinforcement: Cantilever walls often include reinforcement elements, such as steel bars or geosynthetic materials, to enhance their strength and stability. These reinforcements are embedded within the concrete stem and base.

Cantilever walls offer several advantages, including their structural efficiency, ability to handle large loads and suitability for various soil conditions. However, they require careful design and construction to ensure their stability and functionality.

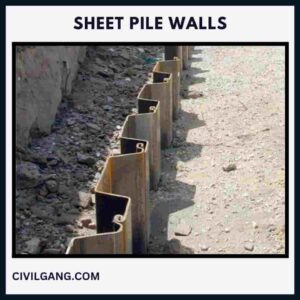

Sheet Pile Walls

Sheet pile walls are commonly used in waterfront structures and areas with soft or loose soil. They consist of interlocking steel, vinyl, or wood sheets that are driven into the ground vertically.

The sheets provide support against soil pressure and act as a barrier to prevent water seepage. Sheet pile walls are suitable for both temporary and permanent applications and are often used in marine construction projects.

Free-standing sheet pile walls are a type of retaining wall that consists of interlocking sheet piles driven vertically into the ground to create a barrier against soil or water.

Unlike traditional cantilever walls or anchored walls, free-standing sheet pile walls do not rely on external supports or tiebacks for stability. The sheet piles themselves provide the necessary resistance to soil or water pressure.

Here are the key characteristics and features of free-standing sheet pile walls:

- Sheet Pile Materials: Sheet piles are typically made of steel, but they can also be made of other materials such as vinyl or composite materials. Steel sheet piles are commonly used due to their strength, durability, and ease of installation.

- Interlocking Mechanism: Sheet piles are designed with interlocking features on their edges, allowing them to be connected and form a continuous wall. The interlocking mechanism provides stability and prevents the individual sheet piles from separating or shifting.

- Vertical Alignment: Sheet piles are driven vertically into the ground, forming a continuous wall without any inclination or batter. The vertical alignment allows for efficient use of space and maximizes the retained area.

- Driving Techniques: Sheet piles are installed using various driving techniques, including impact driving, vibratory driving, or pressing. The chosen technique depends on factors such as soil conditions, sheet pile material, and available equipment.

- Retained Height: Free-standing sheet pile walls are generally suitable for relatively low to medium-height applications. The height limitations depend on factors such as soil conditions, sheet pile material, and design parameters. For taller walls, additional considerations such as tiebacks or anchors may be required.

- Anchorage and Bracing: While free-standing sheet pile walls do not rely on external supports, they may require anchorage or bracing in certain situations. Anchors or braces can be used to enhance the stability of the wall, especially in cases where the retained soil or water pressure is significant.

- Waterproofing and Drainage: Free-standing sheet pile walls can be designed to be watertight, effectively preventing water seepage through the wall. Additionally, proper drainage systems such as weep holes or drainage pipes may be incorporated to manage groundwater or relieve hydrostatic pressure.

Free-standing sheet pile walls are commonly used in various applications, including:

- Temporary Earth Retention: They are frequently employed as temporary structures during construction projects, providing excavation support and preventing soil collapse.

- Cofferdams: Sheet pile walls are often used in the construction of cofferdams, which are temporary enclosures to create a dry work area for construction activities in water bodies.

- Flood Protection: Sheet pile walls can serve as flood protection barriers, preventing water from inundating protected areas during flood events.

- Shoreline and Bank Stabilization: They are utilized to stabilize shorelines, riverbanks, and coastal areas, protecting against erosion and maintaining the stability of the land.

- Bulkheads and Cut-off Walls: Sheet pile walls are also employed as bulkheads or cut-off walls in marine or waterfront structures, providing structural support and preventing water infiltration.

The design and construction of free-standing sheet pile walls require careful consideration of factors such as soil conditions, water table, loadings, and desired performance.

By choosing appropriate sheet pile materials, driving techniques, and incorporating necessary reinforcements or bracing, free-standing sheet pile walls can provide effective and efficient solutions for soil or water retention in various engineering applications.

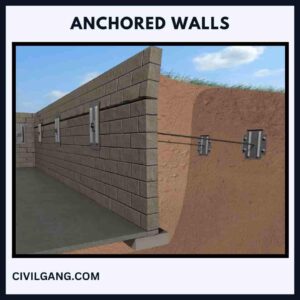

Anchored Walls

Anchored walls are designed to resist higher soil pressures and are used when the available space for constructing a gravity or cantilever wall is limited. These walls use tensioned anchors that extend into the soil behind the wall to provide additional support.

The anchors are typically made of steel or reinforced concrete and are secured by grouting or mechanical means. Anchored walls are suitable for taller retaining walls or in areas with poor soil conditions.

Anchored walls, also known as tieback walls, are retaining walls that incorporate additional reinforcements to enhance their stability and resistance to soil pressure. Anchors or tiebacks are used to transfer the lateral soil forces to a more stable area behind the wall.

These reinforcements typically consist of steel tendons or cables that are installed horizontally into the soil behind the wall and anchored to a stable foundation or a deadman, which is a mass of concrete or soil that provides resistance against the anchor forces.

Anchored walls are often used in situations where the soil conditions or design requirements exceed the capabilities of free-standing walls. They are effective in retaining higher loads or when dealing with unstable soils.

Anchored walls are commonly employed in deep excavations, below-grade structures, or in areas with significant lateral soil pressures.

The key features and advantages of anchored walls include:

- Increased Stability: The inclusion of anchors or tiebacks improves the wall’s resistance to lateral soil pressure, reducing the risk of wall failure or overturning.

- Flexibility: Anchored walls can be designed to accommodate a wide range of soil conditions, including cohesive soils, granular soils, or mixed soil profiles.

- Space Efficiency: By utilizing anchors or tiebacks, the need for a wider base or increased wall thickness can be reduced, optimizing land use and construction space.

- Versatility: Anchored walls can be used in various applications, including deep excavations, basement walls, retaining walls, bridge abutments, and other structures where lateral soil pressure is a concern.

- Design Adaptability: Anchored walls can be designed to meet specific project requirements, considering factors such as soil properties, loadings, groundwater conditions, and the desired level of performance.

It is important to note that anchored walls require careful design, construction, and monitoring to ensure their effectiveness and long-term stability.

Engineering expertise and consideration of site-specific factors are necessary to determine the appropriate design parameters, anchor spacing, and reinforcement requirements for a given project.

In summary, free-standing walls rely on their own weight and mass for stability, while anchored walls incorporate additional reinforcements, such as anchors or tiebacks, to enhance stability and resistance to lateral soil pressures.

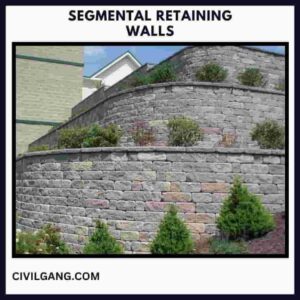

Segmental Retaining Walls

Segmental retaining walls (SRWs) are a modular type of free-standing retaining wall that consists of individual interlocking blocks. These blocks are often made of concrete and have specialized shapes that allow them to fit together like puzzle pieces.

SRWs provide versatility in design and are suitable for both straight and curved wall configurations. They can be used for a wide range of applications, from residential landscaping to large-scale commercial projects.

Free-standing segmental retaining walls (SRWs) are a type of retaining wall system that consists of individual interlocking concrete or masonry units stacked horizontally to create a cohesive and stable wall structure.

These walls are self-supporting and do not rely on external reinforcements or tiebacks for stability. They are commonly used in landscaping and civil engineering projects for soil retention and grade change management.

Here are the key characteristics and features of free-standing segmental retaining walls:

- Interlocking Units: Free-standing SRWs are constructed using individual precast concrete or masonry units that are designed with interlocking features. These interlocks allow the units to be stacked together without the need for mortar or adhesive, creating a stable and cohesive wall system.

- Self-Weight Stability: The stability of free-standing SRWs is achieved through the self-weight of the units and the friction between the units and the compacted backfill. The weight and interlocking mechanism of the units resist the lateral soil pressure and provide stability to the wall.

- Reinforcement: While free-standing SRWs do not require external reinforcements for stability, they may incorporate internal reinforcement elements for added strength and resistance to soil pressure. These reinforcements, such as steel or geosynthetic straps, are embedded within the units and extend into the compacted backfill.

- Versatility: Free-standing SRWs offer versatility in design and application. They can be used in various landscape and civil engineering projects, including residential landscaping, commercial developments, roadways, and slope stabilization. The modular nature of the units allows for flexibility in creating curved walls, corners, steps, and other design features.

- Aesthetics: SRWs come in a variety of textures, colors, and finishes, allowing for customization to enhance the aesthetics of the wall and complement the surrounding environment. Some units are designed to resemble natural stone or other materials, providing an attractive appearance.

- Drainage: Proper drainage is essential for the performance of SRWs. These walls are typically designed with built-in drainage features, such as open vertical channels or weep holes, to allow for the efficient drainage of water behind the wall and prevent hydrostatic pressure buildup.

- Construction Efficiency: Free-standing SRWs are relatively quick and easy to install compared to traditional retaining wall systems. The interlocking units can be stacked and leveled, and the wall can be constructed in a stepped-back fashion, reducing the need for extensive excavation and formwork.

- Height Limitations: The height limitations of free-standing SRWs depend on several factors, including the unit design, soil conditions, and engineering considerations. Generally, these walls are suitable for retaining walls of up to several meters in height. For taller walls, engineering analysis and design expertise are required, and additional considerations such as soil reinforcement or tiebacks may be necessary.

Free-standing segmental retaining walls offer an efficient and cost-effective solution for soil retention, grade changes, and landscaping projects. Their modular design, aesthetic options, and ease of installation make them a popular choice for both residential and commercial applications.

Proper design, construction, and compaction of the backfill are essential to ensure the stability and long-term performance of these walls.

Considerations for Design and Construction of Free-Standing Retaining Walls

Designing and constructing free-standing retaining walls require careful consideration of various factors to ensure the structural integrity, stability, and longevity of the wall.

This article discusses key considerations for the design and construction of free-standing retaining walls, including site evaluation, wall geometry, material selection, drainage, reinforcement, and construction techniques.

By addressing these considerations, engineers and builders can create robust and effective retaining walls.

Introduction

Free-standing retaining walls are essential structures used in civil engineering and landscaping to provide stability, prevent soil erosion, and create level surfaces.

Designing and constructing these walls require a thorough understanding of site conditions, soil properties, and the loads the walls will bear. This article highlights important considerations for the design and construction process, ensuring the durability and safety of free-standing retaining walls.

Site Evaluation

Before embarking on the design process, a comprehensive site evaluation is necessary. The following factors should be assessed:

Soil Conditions:

Understanding the soil properties, such as cohesion, angle of friction, compaction characteristics, and water content, is crucial. Soil tests, including geotechnical investigations, should be conducted to determine the soil’s bearing capacity and potential for settlement.

Groundwater Level:

The groundwater level can significantly impact the stability of the retaining wall. It is essential to evaluate the depth and fluctuations of the water table to determine the appropriate wall design and drainage system.

Slope Stability:

The stability of the existing slopes adjacent to the retaining wall must be assessed. Slope failure or movement can exert additional lateral pressure on the wall, compromising its integrity.

Wall Geometry:

The geometric design of the retaining wall is a vital aspect of its functionality and aesthetics. The following factors should be considered:

Height and Slope:

The height of the wall will influence the design and required reinforcement. Taller walls may require additional structural elements, such as tiebacks or soil anchors, to counteract the increased lateral pressure.

The slope of the wall face should be carefully determined to prevent soil instability and ensure proper drainage.

Wall Batter:

The inclination or setback of the wall face, known as the wall batter, contributes to the stability and aesthetics of the structure. The appropriate batter angle should be determined based on the soil conditions and the wall’s intended purpose.

Curvature:

In some cases, a curved or terraced wall may be necessary to accommodate site constraints or enhance visual appeal. Curved walls require special attention during design and construction to ensure uniform load distribution and stability.

Material Selection:

Choosing the right materials for the retaining wall is crucial for its structural integrity and durability. Consider the following factors when selecting materials:

Retaining Wall Blocks:

Various materials can be used for retaining wall blocks, such as concrete, stone, brick, or timber. The choice depends on factors such as aesthetics, budget, availability, and the height and load requirements of the wall.

The blocks should have sufficient strength and interlocking capabilities to resist lateral pressure effectively.

Backfill Material:

The backfill material placed behind the retaining wall is vital for proper drainage and stability. Granular materials, such as crushed stone or gravel, are commonly used for their excellent drainage properties and compaction characteristics.

The backfill material should be compatible with the wall blocks and allow for adequate compaction to minimize settlement.

Drainage

Effective drainage is essential for retaining wall performance and longevity. Consider the following drainage considerations:

Back Drainage:

A drainage system, such as perforated pipes or geocomposite drains, should be installed behind the retaining wall to collect and redirect groundwater. This prevents hydrostatic pressure buildup.

What Is a Free Standing Wall?

A freestanding wall is a standalone wall that is not connected at either end to a building or other structure, and not restrained along the top. Brick front fences are typical examples of freestanding walls.

What Are Sheet Piles Used for?

Sheet piles are installed in sequence to design depth along the planned excavation perimeter or seawall alignment. The interlocked sheet piles form a wall for permanent or temporary lateral earth support with reduced groundwater inflow.

Segmental Retaining Wall Cost

On average, building a retaining wall costs $23 per square foot. For the more budget-conscious, retaining wall prices average at $19 per square foot. On the upper end, retaining wall costs are around $50 per square foot.

Retaining Walls Construction

How to Build a Retaining Wall

- Step 1: Excavate your space.

- Step 2: Lay a substantial gravel base.

- Step 3: Compact the gravel with a large compactor.

- Step 4: Pinup filter fabric.

- Step 5: Install perforated pipe for water drainage.

- Step 6: Lay the first course of block and fill with gravel.

Wood Retaining Wall Construction

How to Build a Wood Retaining Wall

- Step 1: Remove Soil and Dig a Trench.

- Step 2: Prepare the Timbers.

- Step 3: Drive Rebar Stakes.

- Step 4: Drill Holes for Spikes.

- Step 5: Lay the Drainpipe.

- Step 6: Put the Deadmen and Tiebacks in Place.

- Step 7: Lay the Remaining Courses.

- Step 8: Fill With Topsoil.

Should Retaining Wall Blocks Be Filled?

After each row is completed, you should use backfill to reinforce the retaining wall. Use crushed gravel to fill in the back and sides of your blocks. Backfill helps with water drainage. Compact the backfill before starting on the next row of blocks.

Disadvantages of Retaining Wall

Disadvantages

- Costly due to other materials required for installation – steel, concrete footings, additional cost to create different finishes.

- Labour intensive.

- Can look sterile or harsh look in their raw state.

Disadvantages of Gravity Retaining Wall

Disadvantages of Retaining Wall:

- Due to severe pressure or drastic temperature changes, certain retaining walls develop vertical fissures in the poured concrete.

- Some retaining walls, such as brick walls, cannot withstand severe soil pressure, resulting in brick breakage or foundation failure.

Free Standing Block Wall Height

Most retaining walls, whether load-bearing or not, average between 3 and 4 feet in height. As a general rule, you do not want to build any sort of structure over 4 feet in height without including some type of structural support within.

Like this post? Share it with your friends!

Suggested Read –

Leave a Reply